Every great helmet starts with insight. That’s why research and strategy are the backbone of our development process—shaping each decision with purpose and precision.

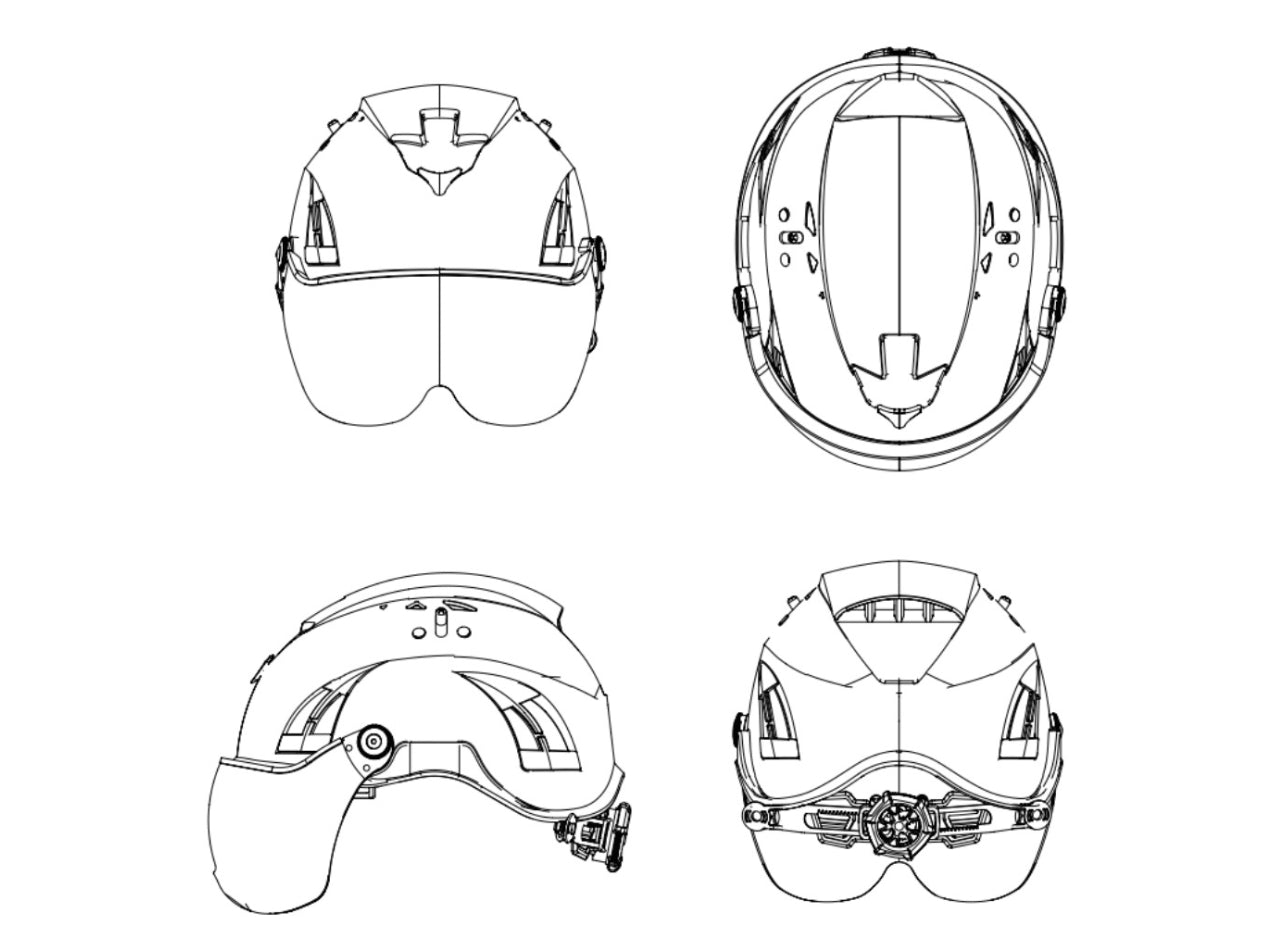

We don’t just dive into design. First, we ask the right questions—what are the real-world risks? What do users truly need? And where is the market heading? By grounding innovation in science, user behavior, and industry trends, we uncover new opportunities to tackle impact challenges and explore emerging categories.

From competitive benchmarking and category analysis to staying on top of safety regulations, every step is designed to bring clarity to your concept and strength to your brand.

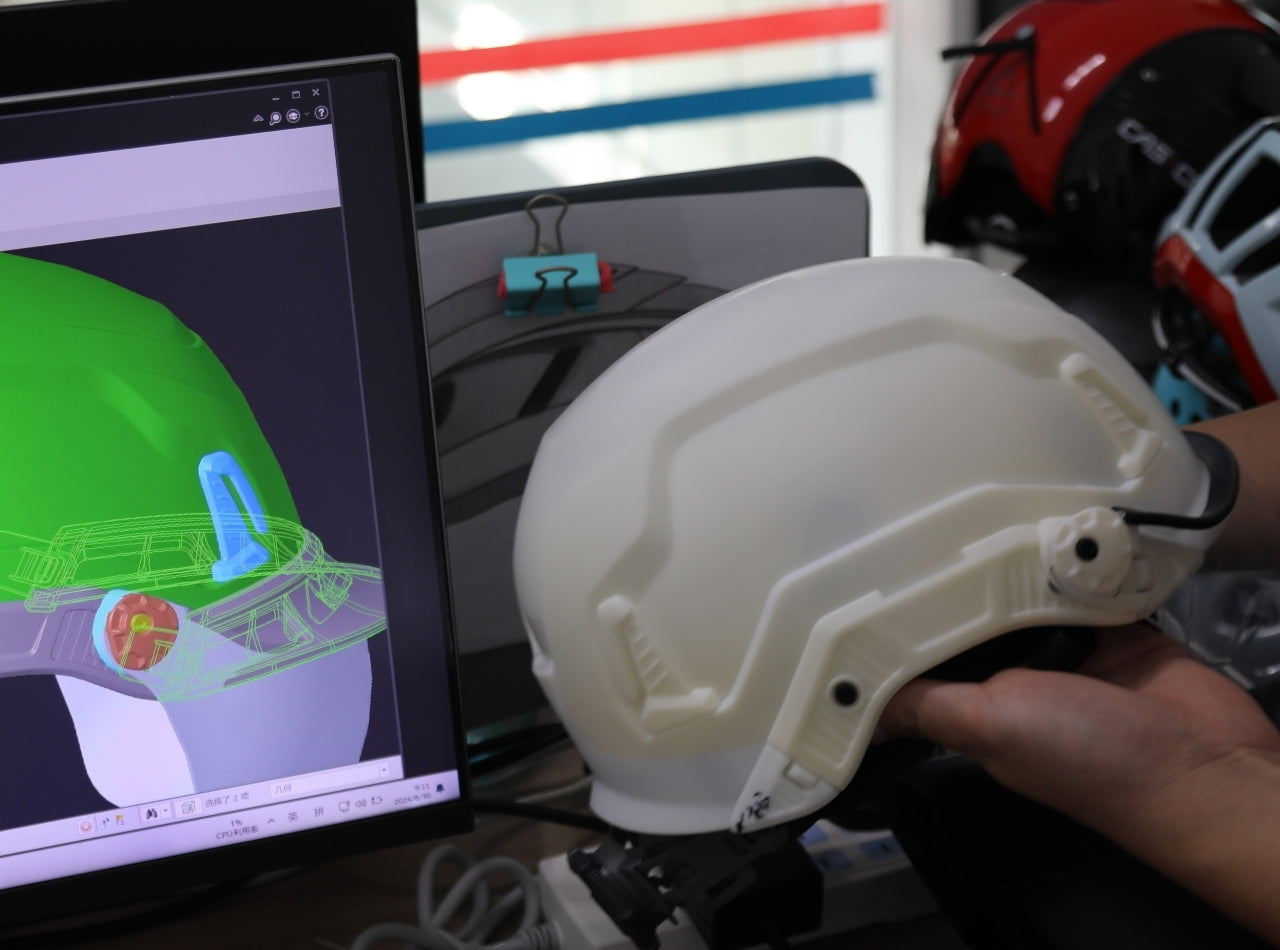

It’s a collaborative process. Feedback from users, partners, and field testing helps us refine the details—whether that’s better ventilation, a more secure fit, or lightweight comfort. We’re not just here to develop helmets—we’re here to build smarter solutions that actually make a difference.